flotation beneficiation process YouTube

#0183;#32;this is the whole flotation beneficiation process; it is used in gold, lead, zinc, copper beneficiation line.

WhatsApp)

WhatsApp)

#0183;#32;this is the whole flotation beneficiation process; it is used in gold, lead, zinc, copper beneficiation line.

Vietnam Kra 800tpd Graphite Ore Processing_PlantXinhai Know More. 26 May 2016 Vietnam Kra 800tpd #Graphite Ore Dressing Plant Project is one of the successful Through the mineral processing test before beneficiation, Xinhai the graphite had great washability, the flotation process

Then, general aspects of graphite flotation are briefly explained. Finally, the recovery by flotation of kish graphite, which exists in flue dust occurring during the iron and steel making process is presented, with the basic investigation as well as the plant application.

The flotation rate depends on the size of the spherolites, the flotation distance on the travel speed and the time available for flotation, and time in turn is a function of wall thickness. In thickwalled castings made of hypereutectic nodular graphite cast iron large spherolites are formed which have plenty of time for flotation due to the long solidification periods.

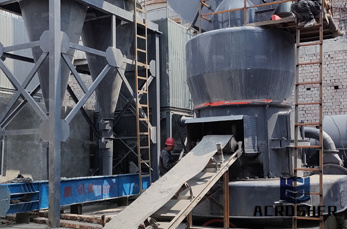

Graphite ore flotation process is an efficient graphite ore deep processing technology, it can greatly increase the application of graphite ore area, selected graphite ore concentrate, can meet the diverse needs of various fields of production. In this case, Graphite natural floatability is very good, generally use the flotation method, with neutral oil can be harvested. But we should pay

Graphite Flotation Screen. Graphite beneficiation process most low grade graphite ores are crystalline and respond very well to flotation treatment for graphite recovery where a fairly high percentage of the graphite in the comminuted ore is in the 100 mesh it is possible

Yuechenglins research confirmed this point. In his experimental study of the scale graphite rapid flotation process, he concluded that the rapid flotation process can make the grade of % of the raw ore, and get the grade of % and the recovery of % of the graphite concentrate.

Can anyone suggest what will be the next process after processing and beneficiation of low grade graphite ore by froth flotation? What flowsheet is my plant needing and how I remove coated graphite form the clay particle after flotation?

graphite flotation process in chemistry HFC Refrigerants (55) HST Hydraulic Cone CrusherHST series hydraulic cone crusher is combined with technology such as machinery, hydraulic pressure, electricity, automation, intelligent control, etc., representing the most advanced crusher technology in the world.

#0183;#32;FLOTATION OF KISH GRAPHITE Basic Flotation Tests for Some Kinds of Flue Dust Several kinds of flue gas occur from unit operations in the iron and steel making process. The gas contains a high percentage of dust which consists of fine iron oxides, coke breeze, amorphous and crystalline graphites, etc..

Process graphite beneficiation. graphite beneficiation method include flotation, electrostatic separation, gravity separation, etc. flotation is the most widely used process. graphite mineral processing are mainly suitable for all kinds of graphite with different crystal habit and graphite accompany with mica, etc silicate minerals or pyrite.

Owing to there being different types of finegrained minerals, the process of flotation also varies. Generally, it can satisfy the requirement of separating fine coal only through one flotation cycle, however, for flotation of graphite, one flotation operation cannot meet industrial requirements [13].

Graphite Process Graphite Extraction Graphite Flotation. The composition properties and distribution of graphite ores are different so the graphite processing technologies are various Emailxlyinxinhaimining net Toggle navigation Home About us Mineral process Mineral process 8 Factors Affecting Fluorite Flotation Process 2020 07 5 Methods of Mica Separation 2020 07 240507.

WhatsApp)

WhatsApp)