User Guidelines | Recycled Materials Resource Center

Recycled Materials Resource Center College of Engineering 2204 Engineering Hall 1415 Engineering Drive Madison, WI

WhatsApp)

WhatsApp)

Recycled Materials Resource Center College of Engineering 2204 Engineering Hall 1415 Engineering Drive Madison, WI

Blast Furnace Slag User Guideline Granular Base INTRODUCTION. Aircooled blast furnace slag ACBFS is considered by many specifying agencies to be a. Prices / Quote. Use Of Steel Slag As A Granular Material Volume Expansion.

[ Granular Base] [ Embankment or Fill] [ Material Description] BLAST FURNACE SLAG: User Guideline: Asphalt Concrete: INTRODUCTION. Aircooled blast furnace slag (ACBFS) is considered by many specifying agencies to be a conventional aggregate and can replace both coarse and fine aggregates in asphalt paving applications.

#0183;#32;The use of slag in concrete has several benefits, including reduced energy, reduced greenhouse gas emissions, and reduced use of raw materials. Various types of slag are produced: Blastfurnace slagThe nonmetallic product, consisting essentially of silicates and aluminosilicates of calcium and of other bases, that is developed in a molten condition simultaneously with iron in a blast furnace.

Ground granulated blast furnace slag (GGBS) is a byproduct from the blastfurnaces used to make iron. Blastfurnaces are fed with controlled mixture of ironore, coke and limestone, and operated at a temperature of about 1,500#176;C. When ironore, coke and limestone melt in the blast furnace, two products are producedmolten iron, and molten slag.

Granulated blast furnace slag should contain calcium oxide (CaO), magnesium oxide (MgO), and silicon dioxide (SiO 2), the sum of which should account for at least twothirds of the mass. The remaining third contains aluminium oxide (Al 2 O 3), with small amounts of other compounds.

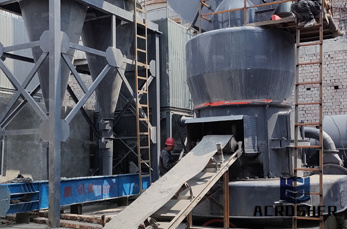

Literature review of a granulated blast furnace slag as a replacement of sand Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Literature review of a granulated blast furnace slag as a replacement of sand, quarry, aggregate, and different kinds of minerals.

Granulated Blast Furnace Slag gt;90% Section 4: First Aid Measures Description of first aid measures Eye If in eyes, hold eyelids apart and flush continuously with running water. Continue flushing until advised to stop by a Poisons Information Centre, a doctor, or for at least 15 minutes.

#0183;#32;Synonyms: Slag cement, ground granulated blast furnace slag (GGBFS), granulated blast furnace slag (GBFS), Slag Product Form: Solid / powder or granular Intended Use of Product: Ground granulated blast furnace slag is used as an additive with portland cement in combination with water and aggregates to form concrete.

Granulated Blast Furnace Slag Granulated blast furnace slag is a glassy granular material that varies, depending on the chemical composition and method of production, from a coarse, popcornlike friable structure greater than mm (No. 4 sieve) in diameter to dense, sandsize grains passing a

Gradation: Blast furnace slag should be crushed and screened to produce a material that satisfies the grading requirements of granular base and subbase specifications, such as AASHTO M147. Compacted Density : The compacted density varies with size and grading of the slag, method of measuring, and bulk specific gravity of the slag.

blast furnace [1]. It results in the production of gas com pounds (blast furnaces gas), of liquid (slag castiron), and of solid (gas dust). The granulated blast furnace slag may be used to make blast furnace slag cement either by being interground with the Portland cement clinker or by grinding the blast furnace slag separately and then blend

Ground Granulated Blast Furnace Slag (GGBS) The importance of Ground Granulated Blast Furnace Slag (GGBS) lies in its greener way to become a substitute in concrete material. GGBS being a waste material, it needs proper method for disposal. So incorporating this waste material in concrete can reduce the depletion of conventional concrete components such as cement, fine aggregate and coarse

BLAST FURNACE SLAG User Guideline. Portland Cement Concrete. INTRODUCTION. Ground granulated blast furnace slag (GGBFS) has been used for many years as a supplementary cementitious material in Portland cement concrete, either as a mineral admixture or as a component of blended cement. The use of GGBFS in Portland cement is governed by AASHTO M302.

Ground granulated blast furnace slag (GGBS) was employed as the main component of an alternative binder. Ground agricultural gypsum and constructiongrade hydrated lime were used as activators in the proportions of :: (GGBS:gypsum:lime) by mass as previously discussed (Oliveira et al., 1999).Sisal (Agave sisalana) field byproduct was selected from a variety of Brazilian fibrous

Crushed Blast Furnace Slag Blast Furnace Slag User Guideline Granular Base. Gradation: Blast furnace slag should be crushed and screened to produce a material that satisfies the grading requirements of granular base and subbase specifications, such as AASHTO M147.

Corrosivity: Blast furnace slag is mildly alkaline, with a pH in nonstagnant water mixtures in the range of 8 to 10. Despite the fact that blast furnace slag contains a small component of elemental sulfur (1 to 2 percent), the leachate is slightly alkaline and does not present a

WhatsApp)

WhatsApp)