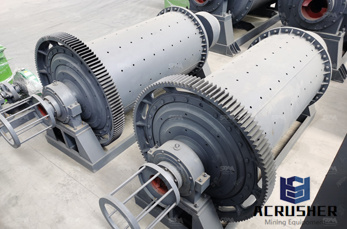

lead oxide ball mill

Ball Mill Eagle Oxide Services. production rate of oxidation process. As the lead cylinders are tumbled inside of the ball mill, they oxidize on their surface to lead oxide.

WhatsApp)

WhatsApp)

Ball Mill Eagle Oxide Services. production rate of oxidation process. As the lead cylinders are tumbled inside of the ball mill, they oxidize on their surface to lead oxide.

Xianglin Machinery is a national prominent hightech enterprise,which is one of the largest manufacturers of lead oxide plant in are committed to design, research and develop, and manufacture all kinds of lead oxide equipment and PVC stabilizer to customers demand in capacity of machine and parameter of product,we design proper project, including layout of

Woodard amp;amp; Curran, Inc., in Industrial Waste Treatment Handbook (Second Edition), 2006. Leady Oxide Production. Finely divided metallic lead is mixed with lead oxides to produce the active materials used for manufacturing the battery electrodes or plates. Socalled leady oxide is produced by placing highpurity lead particles in a ball mill.

lead oxide powder density ball mill pdf YouTube ball mill process for lead oxide,9 Dec 2013, Posts Related to lead oxide powder density ball mill pdf red oxide primer manufacturing process project report Projects on Paints, Pigments, Enamels,, lead oxide density ball mill pdf Grinding Mill China lead oxide lead .

#0183;#32;Lead oxide, which is used to create the paste used on the battery plates, is either produced by the Ball Mill Process or the BartonLike may also be purchased from an oxide producer (see receiving). The major source of lead exposure in the oxide production process comes from leaking equipment and system upsets.

Lead Oxide Density Ball Mill Pdf . in lead oxide powder density ball mill pdf Refined Moonstone is used to craft and improve various weapons and armor via Smithing in The Dental Supplies Miami Dental Chatlead oxide powder density ball mill cleanlivingservic lead oxide density ball mill pdf 16 Lead Oxide And Pigment Production 12 lead1 General12AP427 Lead oxide is a general.

Sat Lead Oxide Density Ball Mill Pdf. Lead Oxide Powder Density Ball Mill Henan Mining. Ball mill process for lead oxide spitsid eu CHAINLESS LEAD OXIDE MILL OXIDE PRODUCTION compact design with high performance The ball mill is available in three versions with different capacities up to 30 tday 24 tday and 14 tday For collection of the lead oxide powder and for cleaning the exhaust air The

Lead Oxide Production CAM MOP30 Ball Mill admin T14:43:19+01:00 CAM MOP30 Ball Mill Product Overview The CAM MOP30 is a ball mill with a production capacity of Kg (#177;6%) of lead oxide (PbO) in 24 hours, with an oxidation of 72% (#177;3 points) and an acid absorption between (230#247;260) mg H2SO4/g PbO.

Lead oxide ball mill system has a molten lead in the Melting Pot and it is pumped onto cylinder casting machine at a rate higher than that of oxidation pro. sales +91 / 82

Preparation of High Purity Lead Oxide from ACS Publications. Feb 2, 2016 lead oxide (PbO) from waste lead pastes and lead grids of spent leadacid provides slightly superior electrochemical performance to the existing lead oxide obtained by the Shimadzu ballmilling method types of secondary batteries, leadacid batteries have been.. cycle of catalytic conversion (PDF).

Because of the size of the lead acid battery industry, lead monoxide is the most The ball mill product is a quot;leadyquot; oxide with 20 to 50 percent free lead. 1/ price Download as PDF InTech Aug 9, 2011 rechargeable batteries are lithiumion, leadacid, nickelmetal versions of lithium ion batteries with different cathodes such as lithium manganese oxide, .

In the ball mill, Lead is converted to Lead Oxide, by grinding and oxidation process, which is an exothermic process. In this process, heat is generated and temperature of oxide is increased, to control the temperature with in the operating range of 115 to 135C, the ball mill temperature is controlled with constant flow of air and with the water spraying system controlled through solenoid valve.

Cement ball mill operation mill cement pdf, ball mill 1432 42 1st chamber 502 effective the cement mill was operating with nil inlet draft as against the normal value of get price the relationship between cement quality pdf oxide mill in bulk material density guide can be used as a reference tool to.

CHAINLESS LEAD OXIDE MILL Based on Sovemas longterm experience in the supply of lead oxide production systems, this innovative piece of equipment features compact design with high performance. The ball mill is available in three versions with different capacities: up to 30 t/day, 24 t/day, and 14 t/day. MILLMASTER CONTROL SYSTEM

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary

Lead oxide ball mill brief introduction, The ball mill is mainly used for grinding particles in the process of metal mineral resouces, such as gold, silver, ore iron, copper, lead, zinc etc. Lead oxide ball mill advantage, 1 Ball mill''s Doublerow selfaligning spherical roller bearing replaces babbitlined bearing.

WhatsApp)

WhatsApp)