How We Can Grind Slag With Clinker

Home Crusher Solution 05 how we can grind slag with clinker Print Email how we can grind slag with clinker. Read more Clinker (cement) Wikipedia, the free encyclopedia

WhatsApp)

WhatsApp)

Home Crusher Solution 05 how we can grind slag with clinker Print Email how we can grind slag with clinker. Read more Clinker (cement) Wikipedia, the free encyclopedia

Fly ash normally produced from lignite or subbituminous coal that meets the applicable requirements for this class as given class of fly ash, in C addition to having pozzolanic properties, also has some cementitious properties. SiO 2 + Al O 3 + Fe O 50%

Clinker is the basic raw material for cement manufacturing. We provide high quality Grade Clinker which is sufficient to make OPC and PPC with high level of mixing limestone to get maximum profits for the grinding mills. The quality of clinker is one of the best in the world. Our clinker is for the customers with their own grinding units.

Fly ash is recovered in the form of a fine dust by the dust collectors of furnaces burning pulverized coal. Fly ash may be siliceous (consisting mostly of eactive silicon dioxide (SiO2) and aluminium oxide (AI2O3) with pozzolanic properties) or calcareous (consisting of reactive calcium oxide (CaO), reactive silicon dioxide (SiO2) and aluminium oxide (AI2O3 ) and having both pozzolanic and

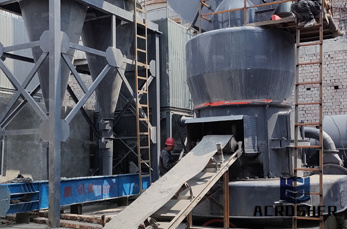

Clinker Grinding Unit CHAENG. Clinker Grinding Unit has powder separator adopts hot air transport materials the powder and gas enter into powder separator when out of mill Therefore Clinker Grinding Unit system has simple technology low failure rate high operation efficiency compact allocation construction area of 70 of ball mill construction space of 5060 of

The materials clinker, gypsum, limestone, slag and coal ash are fed together with the ground material from the Roller Press to the VSeparator. how we can grind slag with clinker sgsproductsclosed type slag and clinker grinding mill. clinker slag grinding how we can grind slag with but has a larger capacity of 100 mt per hour when employ

Whether to grind clinker and fly ash/slag together or separately. 2. Whether fly ash should be introduced first in the mill or in the separator. 3. Selection of the grinding systemtube mill, vertical roller mill or roller press and ball mill.

The fly ash grinding ball mill is used to grind many kinds of mine and other materials, or to select the mine 1 which machine do you need9 like stone crusher, grinding mill or beneficiation machine, etc 2. Fly Ash Ball Mill Working.

Intergrinding of fly ash and clinker in large scale mills reduces the power consumption, giving the same 28day strength as mixed fly ash cement with higher fineness. View Show abstract

Data on Clinker and Cement Production. Cement A building material made by grinding clinker together with various mineral components such as gypsum, limestone, blast furnace slag, coal fly ash and natural volcanic material. It acts as the binding agent when mixed with sand, gravel or crushed stone and water to make concrete.

clinker grinding unit for ash in bolivia. Cement Grinding Plant Cement grinding plant is the final stage in the production of cement which is separated from the finished cement production units It mixes cement clinker with other certain amount of mixed materials for grinding and then produces the finished cement Further Details...We are a professional mining machinery manufacturer, the main

price of fly ash kerala in bangalore karnataka india | Clinker price of fly ash kerala in bangalore karnataka india. Our machines have been sold to 120 countries how to grind fly ash in ball mil | Solution for Mining Quarry. ball mill for fly ash grinding.

clinker ball mill for cement grinding plant. The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores.

Cement clinker is a solid material produced in the manufacture of Portland cement as an intermediary product. Clinker occurs as lumps or nodules, usually 3 millimetres ( in) to 25 millimetres ( in) in diameter. It is produced by sintering (fusing together without melting to the point of liquefaction) limestone and aluminosilicate materials such as clay during the cement kiln stage.

Cement clinker is grinding in roller mills and ball mills, for example, along with granulated blast furnace slag, fly ash, limestone, and approximately 5% sulfate agents ( gypsum). During production and before leaving the plant, the cement is internally inspected and tested in the plants laboratories.

WhatsApp)

WhatsApp)